Engineering Excellence in Precision Fastening

From hydraulic bolt tensioning to torque-controlled fastening, our solutions ensure flawless execution, operational efficiency, and unmatched reliability across offshore, subsea, petrochemical, and power generation sectors.

Our Products & Services

Product Offering

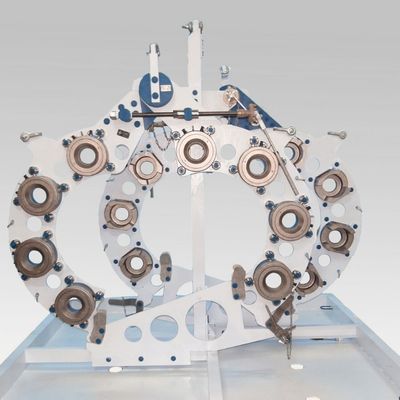

Industry-leading hydraulic bolt tensioners, torque wrenches, and advanced fastening solutions.

On-Demand Rental

Short- and long-term tool leasing for projects requiring precision bolting equipment.

On-Site Technician Support

Certified specialists available for setup, maintenance, and critical joint integrity operations.